Recently, the research team led by Dr. Liang Zhang from the Center for Combustion Energy and the School of Vehicle and Mobility at Tsinghua University has achieved new progress in the intelligent design of low-iridium electrocatalysts for water electrolysis. Previously, the team successfully developed an intelligent multi-component catalyst design strategy that integrates density functional theory (DFT) calculations with Bayesian optimization, and applied it effectively to fuel cell catalyst design (Nature Communications 2024, 415; ACS Catalysis 2025, 4374–4383). Building on this foundation, the team has now extended their strategy to the field of water electrolysis catalysts, developing a novel high-performance, low-Ir catalyst. Experimental validation confirmed its outstanding performance, opening a new pathway for the design of proton exchange membrane (PEM) electrolyzer catalysts with significantly reduced precious metal content. The related study, entitled “Bayesian-Learning-Assisted Catalyst Discovery for Efficient Iridium Utilization in Electrochemical Water Splitting”, was recently published online in Science Advances.

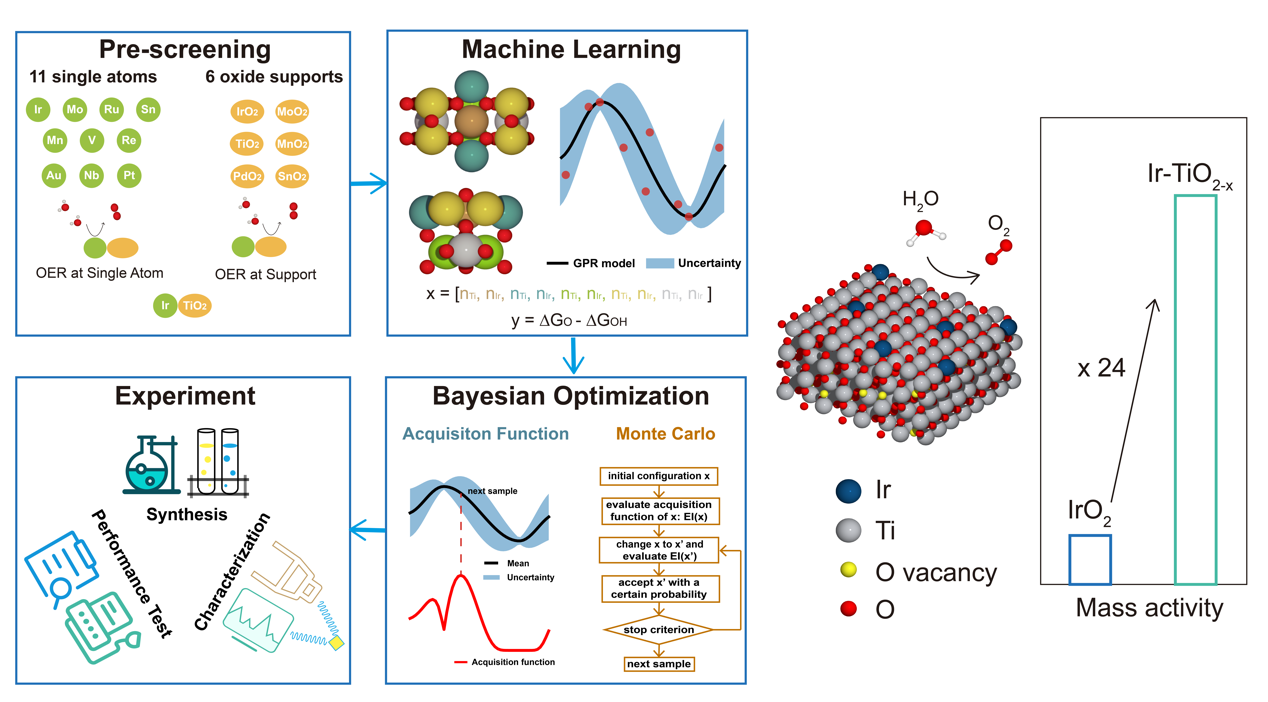

Figure: Schematic illustration of the catalyst design workflow based on theoretical calculations and Bayesian learning.

Green hydrogen is regarded as a core carrier for future sustainable energy, yet its large-scale production requires highly efficient and cost-effective electrocatalysts. In water splitting, the oxygen evolution reaction (OER) remains the key bottleneck for overall efficiency. Currently, mainstream catalysts are based on IrO2, a precious metal oxide. However, the scarcity and high cost of iridium severely limit large-scale applications. Therefore, reducing the precious metal content while maintaining or even improving catalytic performance has become a central challenge in hydrogen production.

In this work, the researchers innovatively combined high-throughput DFT calculations with Bayesian optimization to identify Ir-doped TiO2 as a promising OER catalyst candidate. Using machine learning models, the team precisely predicted the catalytic activity of the Ir–TiO2 system, while optimizing parameters such as surface Ir proportion, chemical ordering, and oxygen vacancy, thereby achieving a data-driven intelligent design of electrocatalysts. DFT screening results revealed that Ir doping significantly enhances the catalytic activity of Ti sites while maintaining the intrinsic activity of Ir. Bayesian optimization further indicated that, under optimized Ir surface distribution and oxygen vacancy introduction, the system exhibits mass activity far exceeding that of commercial IrO2. Guided by these theoretical predictions, the researchers successfully synthesized an Ir atomically dispersed TiO2-x catalyst. The catalyst demonstrated substantially reduced overpotential and significantly improved mass activity compared to commercial IrO2, validating the accuracy and practical value of the theoretical and machine-learning-driven predictions. This study demonstrates the deep integration of Bayesian learning with first-principles calculations, enabling the intelligent design of highly efficient, low-Ir electrocatalysts, and providing an innovative approach for reducing cost and enhancing performance in precious-metal-based catalysis.

The article link: https://www.science.org/doi/10.1126/sciadv.adw0894

Provided by: Liang Zhang's Group

Approved by: Yu Cheng Liu, Xiaoqing You